RPET (recycled polyester) is a better option than virgin polyester - but is it our BEST option? Come with us on a deep dive as we discuss all things virgin polyester, RPET, and the alternative.

Virgin polyester is a very popular material due to its durable qualities and inexpensive price tag. Despite these seemingly positive features, this material comes at a huge cost to the environment. It is made primarily of petroleum, a nonrenewable resource. Not only does production of polyester waste massive amounts of energy, but it also contaminates water with microplastics and toxins in the making process and again when the items are washed.

This is where RPET comes in - recycled polyester. It is very similar to the virgin polyester, but is made up mostly from recycled plastic water bottles. This plastic is made by collecting the bottles, crushing them up, and then heating them to form long strands of yarn which are then knitted into fabric. It is endlessly reusable, but is a much bigger undertaking and requires a longer process than traditional virgin polyester.

RPET is a much better alternative to virgin polyester and produces a much lower carbon footprint and is endlessly reusable. Despite this resource being readily available, most brands still choose to use virgin polyester due to the easier production process. Polyester is an oil-based plastic which means it can take hundreds of years to break down and never really goes away. When it is washed, the fibers (i.e. microplastics) shed and get into waterways and oceans. These are then ingested by aquatic life and accumulate toxins up the food chain. Toxic materials used during production can also leach into the soil when polyester is sent to a landfill, potentially contaminating the local water supply.

RPET is the most common alternative to traditional PET. Though a better solution, it still has the many inherent flaws of polyester and takes lots of energy to produce.

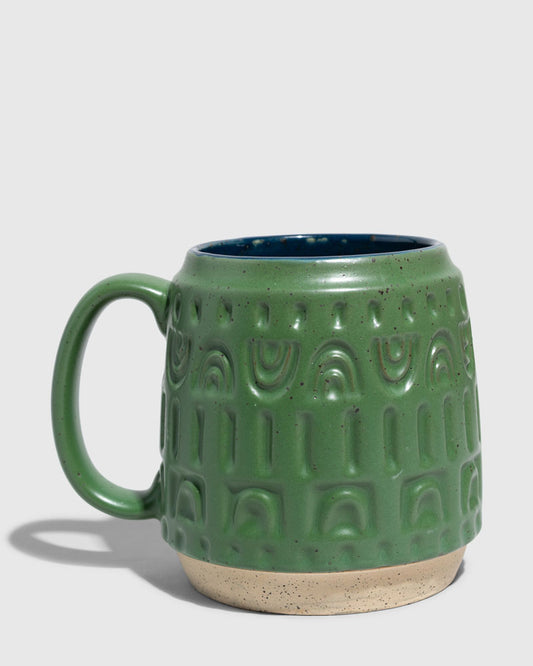

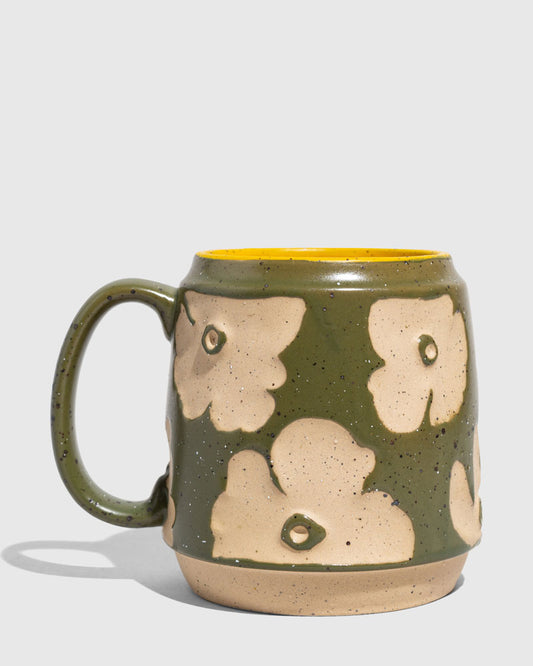

Here, at United By Blue, we are always on the lookout for the next best thing. We love long lasting clothing, but not at the expense of our environmental future. PET takes hundreds of years to decompose and at a cost to the water around it. That's why when we discovered CiCLO, a fabric we can get fully behind, we knew it was an answer for our ongoing search for more sustainable and earth friendly apparel. An update to our infamous graphic tees, this is one you can feel extra good about wearing. CiCLO feels great, looks great AND will decompose within our lifetime (when placed in the correct environment). The synthetic textiles behave like natural fibers when they end up in the environment. This happens by embedding countless biodegradable spots throughout the matrix of the plastic. These spots act like nutrient sources for microbes that naturally exist in the environment. Basically, when textiles made with CiCLO® end up in environments where biodegradation can occur naturally, microbes are attracted to the fibers and can mineralize them at rates comparable to natural fibers, such as wool.

CiCLO® technology is added to polyester and nylon during the melt extrusion process, creating countless biodegradable spots (also known as “nucleation spots”) that are permanently embedded throughout the matrix of the plastic. It will never wash off, and it will not be activated until it is needed – when the fibers end up as pollutants in the environment. Textiles made with CiCLO® fibers look and feel like regular synthetics and can be engineered with high performance characteristics and finishes. Fibers, yarns and finished fabrics have been fatigue tested to ensure traits such as tenacity, pilling resistance and wicking are unchanged. CiCLO® fibers are a great way to reduce the impacts of plastic pollution caused by textiles.

There is no one-size-fits-all solution to this environmental threat from the fast fashion industry - it will take collective action from EVERYONE – manufacturers and brands, consumers and policymakers – to mitigate the microplastics crisis.