From Bottles to Bags:

The (R)evolution™ Bags

◆ ◆ ◆

This year, we decided to rename our bestselling line of recycled polyester bags. Though it was on-brand with our woodsy ethos, “Ridgeline” just didn’t do enough to capture the compelling story of how these bags go from the bottom of a recycle bin to the shelves of our stores. The story is one deserving of a much more inspiring title, one that conveys the surprising lifecycle of a simple plastic water bottle. In fact, it’s one of our favorite manufacturing stories, and it serves as a compelling reason to recycle, even amidst the uncertain state of recycling in the US. So without further delay, allow us to re-introduce you to our favorite recycled bags:

The (R)evolution™ bags

First things first: what is recycled polyester?

Let’s begin with regular polyester, one of the apparel and accessories industry's favorite materials. Polyester is popular because it resists stretch and wrinkles, provides flexibility and comfort, doesn’t shrink, and is easy to wash and wear. It’s easily blended with cotton and wool and can pack serious durability and weather resistance. However, these qualities come with a significant cost. Polyester is not biodegradable. It’s made from crude oil, which tops the charts as the most polluting industry in the world. Similarly, polyester dyes are far from environmentally friendly—in fact, they’re toxic to humans. Lastly, the process of creating polyester is energy-intensive and requires large quantities of water.

Like traditional polyester, recycled polyester is a man-made fabric produced from synthetic fibers. However, instead of utilizing new materials to craft the fabric, recycled polyester makes use of existing plastic. In many cases, those existing plastics are your old water bottles, which are then processed and transformed into products that carry the same characteristics of virgin polyester. Basically, recycled poly gives you the same end use but skips the polluting, energy and water-intensive process of starting from scratch. We are such big fans of recycled poly that we designed an entire bag line around it.

From bottle to bag? How does that work?

The process is actually fairly simple. Recycled polyester is made by breaking down used plastic into small, thin chips, which are processed and eventually spun into yarn. A company named Repreve™, located in North Carolina, manufactures the recycled polyester that makes up our R(evolution) bags. Creating this ultra-durable fiber begins with truckloads of plastic bottles—but just the clear ones, which provide a neutral base for applying dyes. Let’s take a deeper look into what happens next.

Courtesy of Repreve

Sourcing

Recycled polyester makes use of PET (polyethylene terephthalate) waste, which is made up of consumer plastics like soda and waters. These bottles are usually collected locally, then sorted, compacted and baled for reuse.

Processing: gif: use 00:48-00:54 from clip

Collected PET bottles are sorted by color, removed of their labels and separated from other materials like paper and aluminum. They are then ground into flakes, which are washed with detergents to remove any contaminants.

Depolymerization (gif: use 00:07-00:11 from clip

In what’s called “chemical recycling”, the PET flakes are depolymerized, which means that they are broken down to the base-chemical molecule.

Texturing (gif: use 00:45-00:52 from clip

The molten PET polymer is then made into chips and spun into a fiber, which often passes through a crimping machine to create a fluffy, wooly texture.

Textile construction (gif: use 00:55-00:58 from this clip

At this point, the production process is the same as it is for virgin polyester—the spun fiber can either be knit or woven into a textile.

Environmental benefits

By making use of plastic waste instead of using virgin materials, recycled polyester dramatically lowers its environmental impact versus traditional polyester. Some benefits of recycled polyester:

- Reduces reliance on virgin petroleum as a raw material

- Diverts used plastic from landfills

- Prevents used plastic from ending up in our oceans and harming marine life (more on that here)

- Decreases greenhouse gas emissions from creating and processing virgin polyester

- Can be continuously recycled again and again without quality degradation

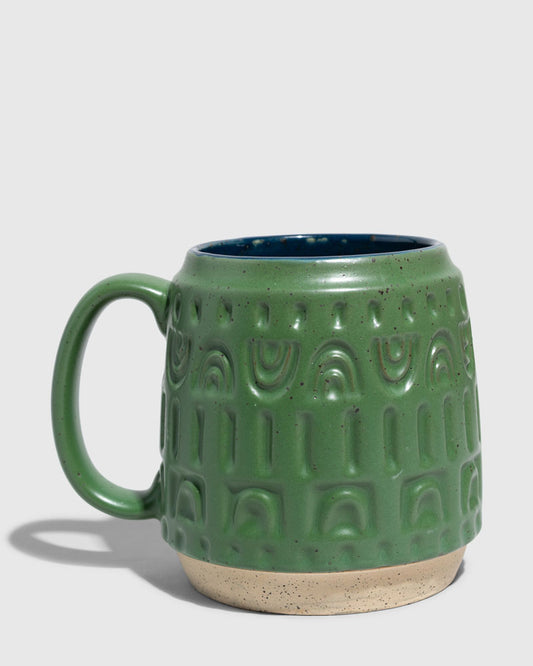

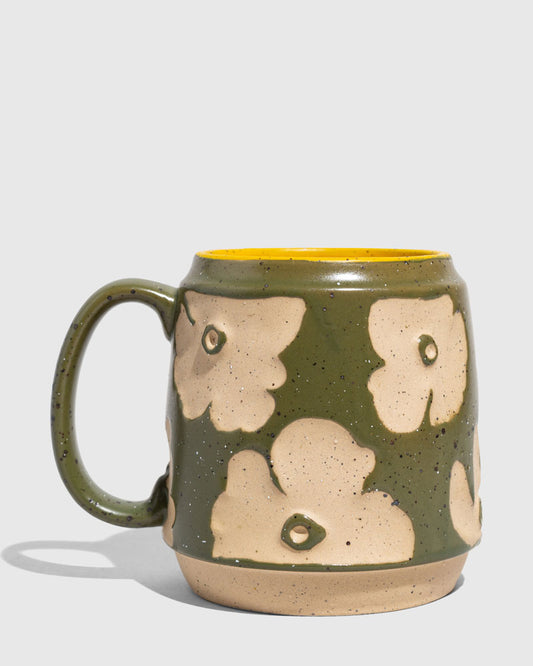

How much recycled polyester went into...

The Bluff Utility Pack?

12 plastic bottles.

The Summit Convertible Tote?

About 17 plastic bottles.

Why We Used Recycled Polyester

With nearly 654,740 tons of clothing being sent to the landfill every year, it’s clear that recycling textiles is becoming increasingly necessary. And our recycling technology is getting better and better. Recycled polyester is a soft yet tough fabric that's a more sustainable option than its conventional counterpart, but maintains all the properties that made polyester so popular since its inception in the ‘40s. From saving water bottles from a life in a landfill to reducing greenhouse gas emissions, it’s a go-to for goods that require high performance durability. Take a look at the finished products with a few of the (R)evolution bags below.

Take these bags as proof—it really does pay to recycle that plastic water bottle. Shop the full collection:

(R)evolution™ Bags